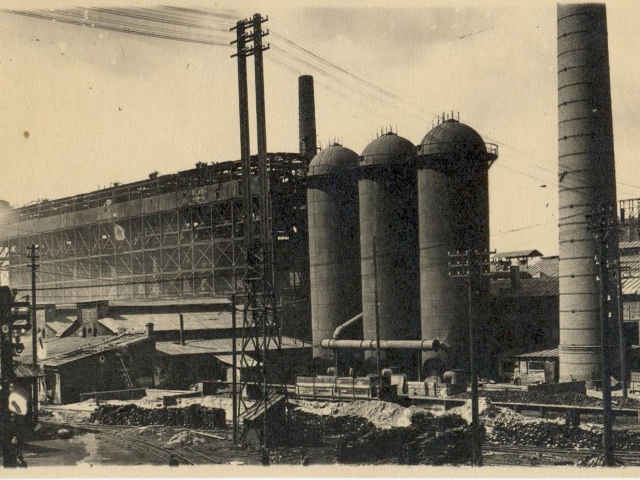

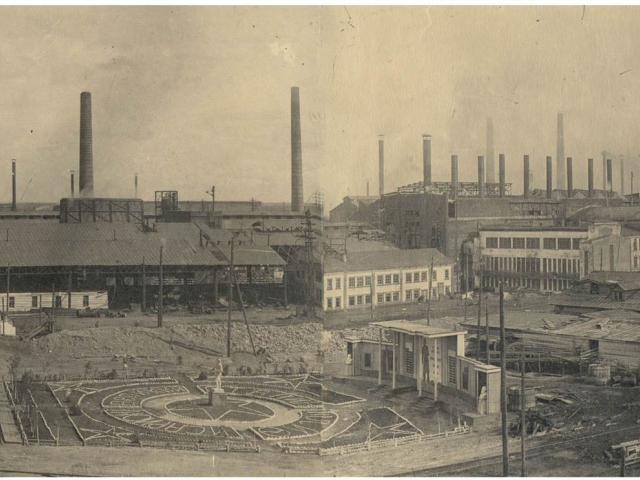

The plant belonged to the Bogoslovsky Mining District. At the time of foundation, the plant was named Nadezhdinsky in honour of the district’s owner, Mrs. Nadezhda Polovtsova. She was wife to Mr. A.A. Polovtsov, a privy councillor in deed and a member of the State Council.

PJSC Nadezhdinski Metallurgical Plant is an integrated iron-and-steel company, which includes a sintering shop, a blast furnace shop, a melting shop, a heavy mill shop, a long product rolling shop, a calibration shop, and other auxiliary subdivisions.

- The plant was founded in 1894; its history dates back to the construction of the Trans-Siberian Railway;

- 350 steel grades;

- hot-rolled round bars, 10-120 mm, 140-300 mm in diameter; hexagon bars, 11-75 mm; square billets, with a side ranging from 100 to 230 mm, as well as calibrated round bars, 10-80 mm in diameter, and hexagon bars, 8-63 mm;

- зthe plant supplies rolled steel to Russian and foreign companies operating in the automotive and aircraft industries, electrical engineering, machine building, and other industries.

STRATEGIC GOAL

The main strategic goal of PJSC Nadezhdinsky Metallurgical Plant, which is the city's major employer with more than a century-long history, is to comply with customer requirements for hot-rolled steel bars, with or without surface finish; calibrated cold-drawn bars and special surface finish bars made of quality and high-quality non-alloyed and alloyed steel grades.

STRATEGY

We will ensure that this goal is achieved by identifying and satisfying customer requests and expectations; solving top-priority quality improvement tasks; upgrading our production facilities, and delivering competitive products to ensure a stable financial standing of the company and staff.

PRODUCTS CURRENTLY AVAILABLE IN STOC